Panier ( 0 )

Panier ( 0 )

KC Printing Machine (Group) Limited

- [Guangdong,China]

- Type d'Affaires:Fabricant , Société de commerce

- principaux marchés: À l'échelle mondiale , Afrique , Amériques , Asie , Caraïbes , Europe de l'Est , L'Europe , moyen-Orient , Europe du Nord , Océanie , Autres marchés , Europe occidentale

- Exportateur:81% - 90%

- certs:CE, ISO9001

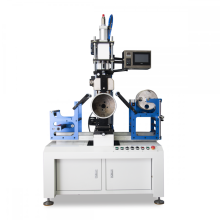

- La description:Machine de transfert de chaleur du capuchon,Machine de transfert de chaleur du cylindre,Machine de transfert de chaleur de bouchon de bouteille pour enfants

Contacter Maintenant

Contacter Maintenant

Contacter Maintenant

Contacter Maintenant